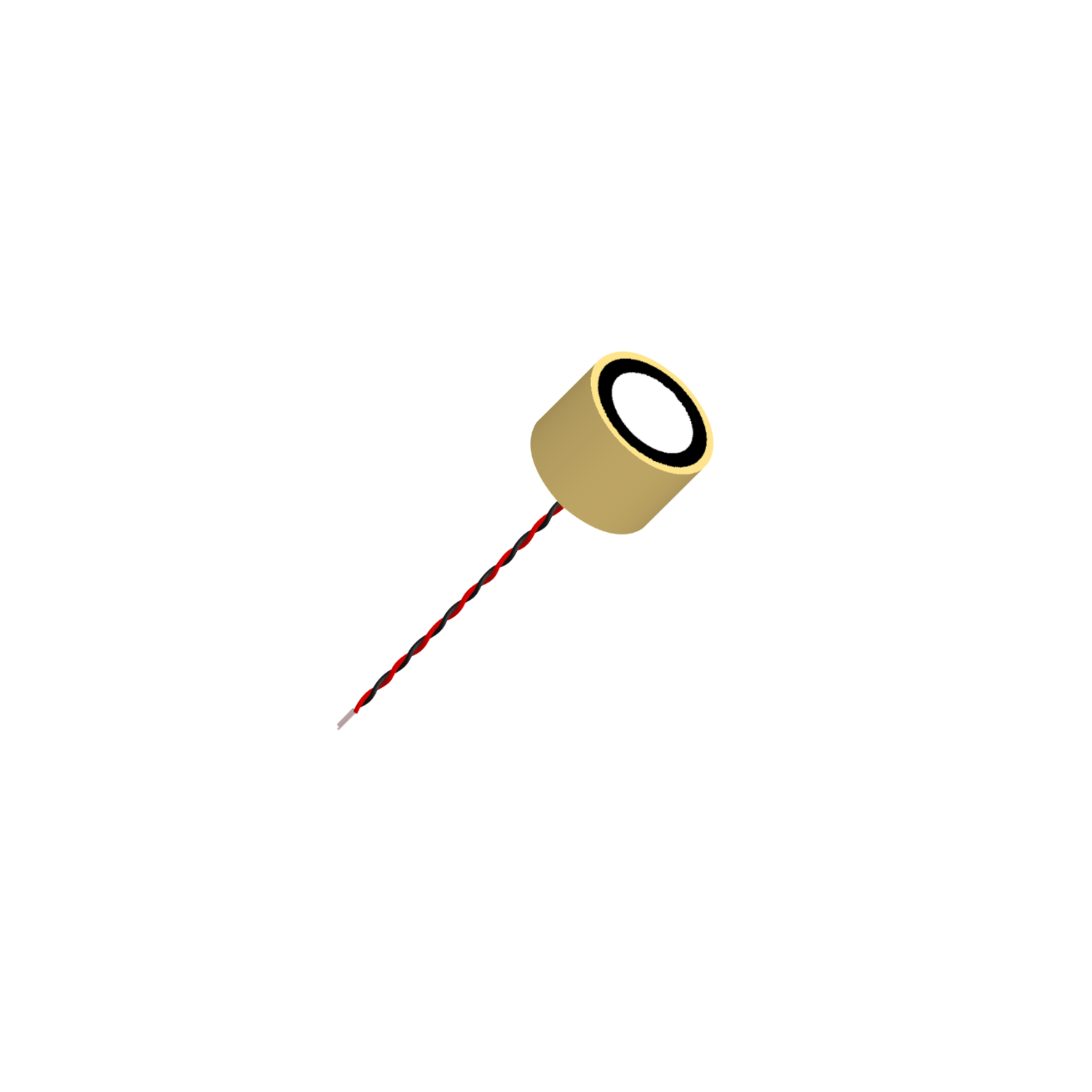

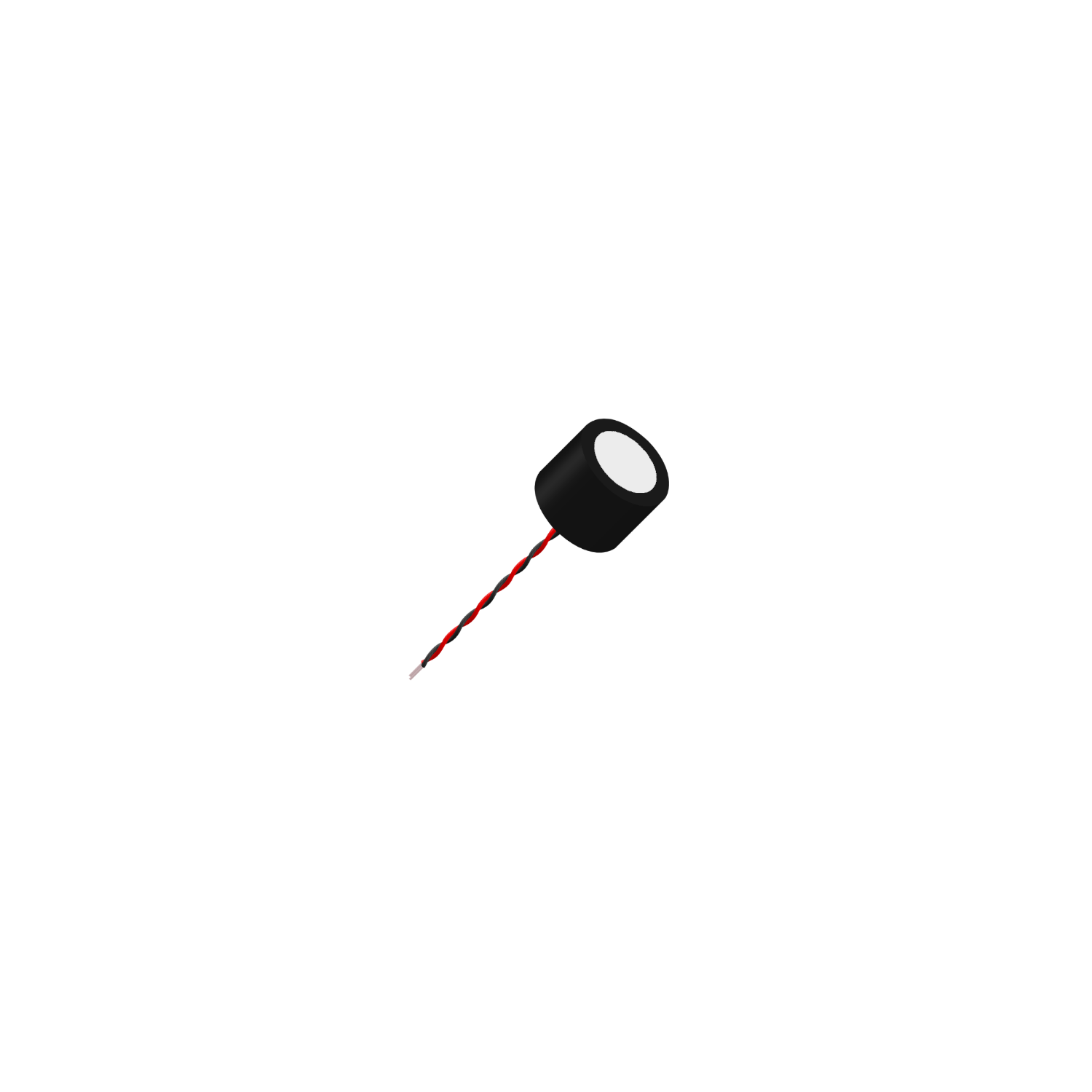

The accurate measurement of wind speed and direction is essential in numerous applications—from meteorology and aviation to the energy sector. Modern anemometers increasingly rely on ultrasonic technology to ensure reliable and contactless measurements. Ultrasonic transducers play a central role in this: they enable the precise determination of air flows without mechanical components, which makes the measurement particularly robust and low-maintenance.

The measuring principle is based on the time difference between ultrasonic pulses transmitted between several sensors. Depending on the wind speed, the time it takes for the signal to travel from one transducer to another changes. These differences can be used to calculate both the speed and direction of the air flow with great accuracy. This method is insensitive to temperature and pressure fluctuations and delivers reliable results even under extreme weather conditions.

In practice, ultrasonic anemometry offers decisive advantages: it operates wear-free, as there are no moving parts, and enables continuous measurement in real time. This is particularly important for applications such as wind turbine control, airport monitoring, or accurate weather forecasting. In addition, ultrasonic anemometers are compact, energy-efficient, and can be easily integrated into digital systems, enabling simple data transfer and analysis.

Companies that rely on ultrasonic technology in anemometry benefit from maximum accuracy, long service life, and a future-proof solution for wind measurement. With its combination of precision, robustness, and digital connectivity, this technology meets the increasing demands placed on modern measurement systems in industry and research.