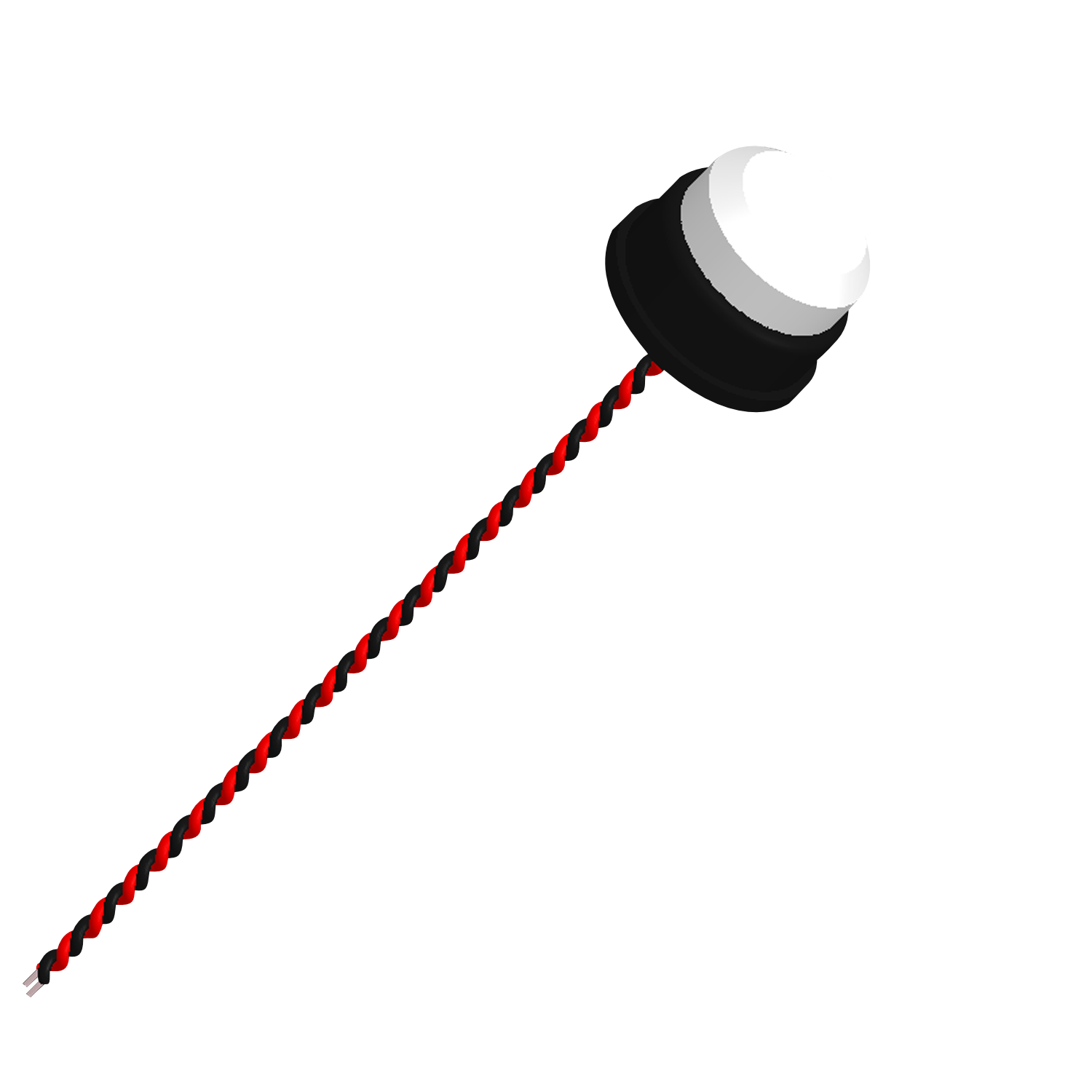

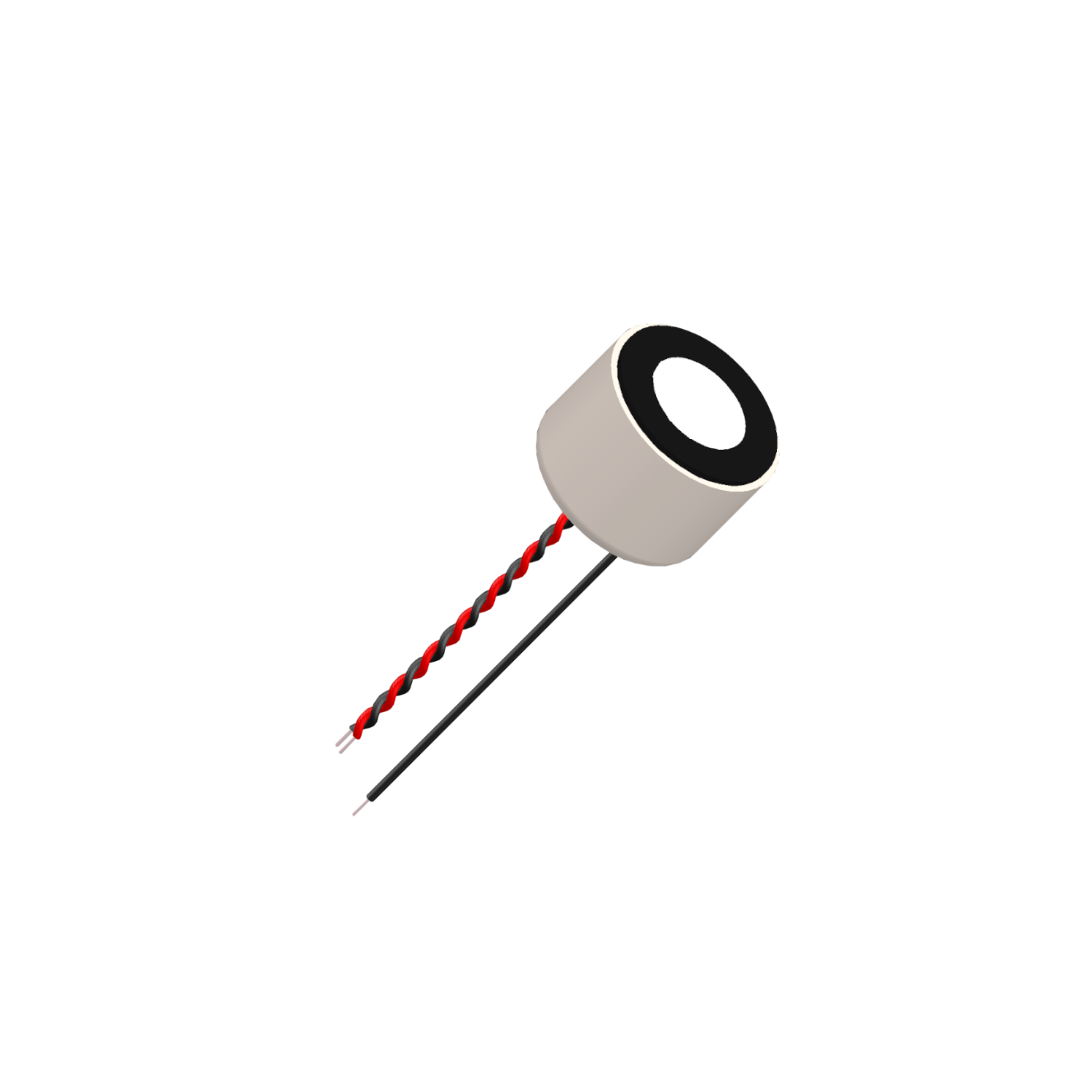

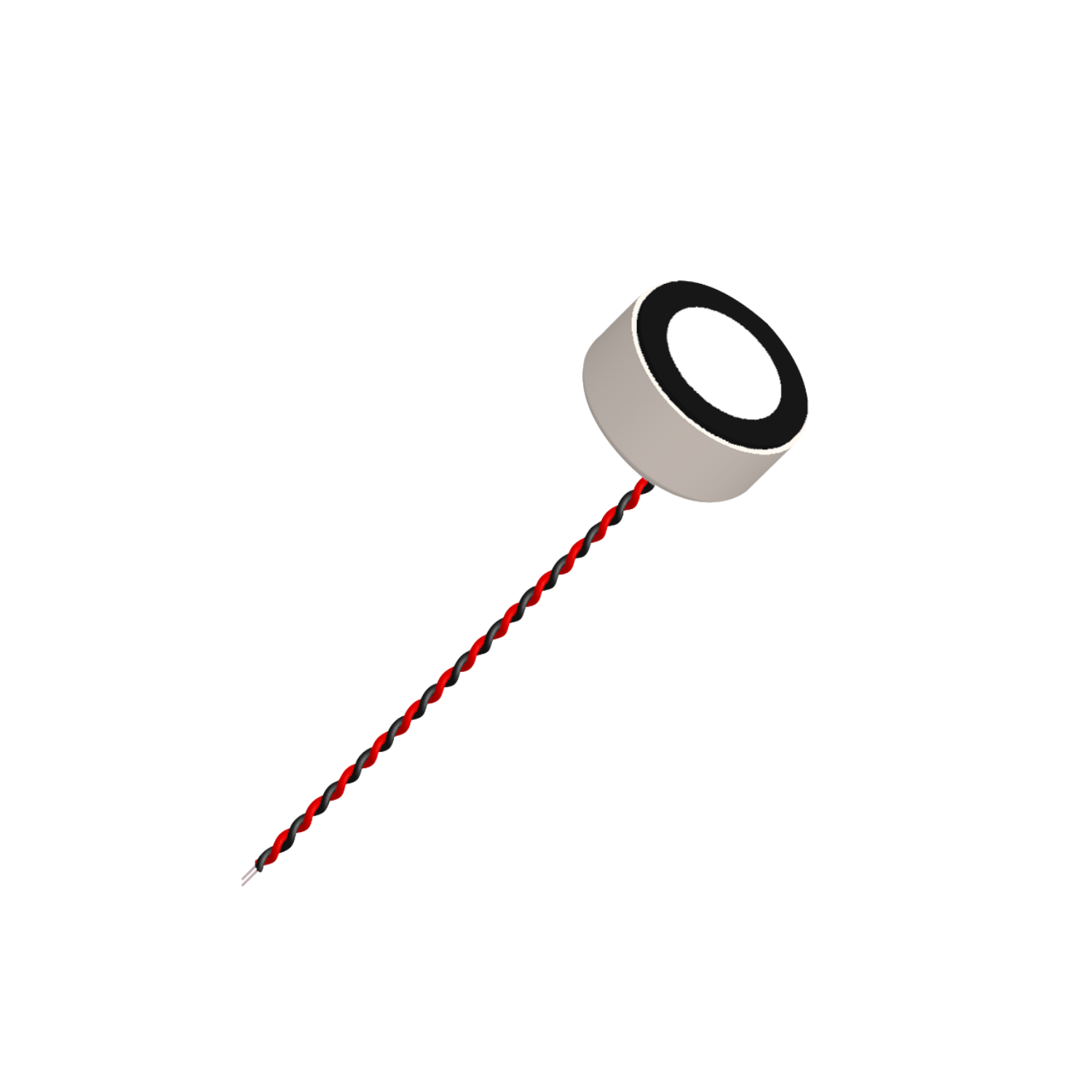

Measuring principle

Web edge control

In the industrial processing of web-shaped materials – whether paper, textiles or transparent films – web edge control with ultrasonic transducers is a key factor for productivity and process reliability. Ultrasonic transducers from SECO Sensor detect even the smallest deviations in the web path in real time and enable rapid correction. Pulsed transducers in multiple arrays have proven themselves for years with customers worldwide.

Our customers use ultrasonic transducers for web edge control for applications such as

- Paper processing

- Money and newspaper printing

- Textile industry

- Film processing