Double sheet detection is an indispensable part of modern production processes in paper, sheet metal, and textile processing. A double sheet occurs when two or more layers enter the system at the same time. This can lead to significant problems such as machine downtime, increased waste, and production errors. To reliably avoid these risks, leading companies rely on double sheet detection using ultrasound.

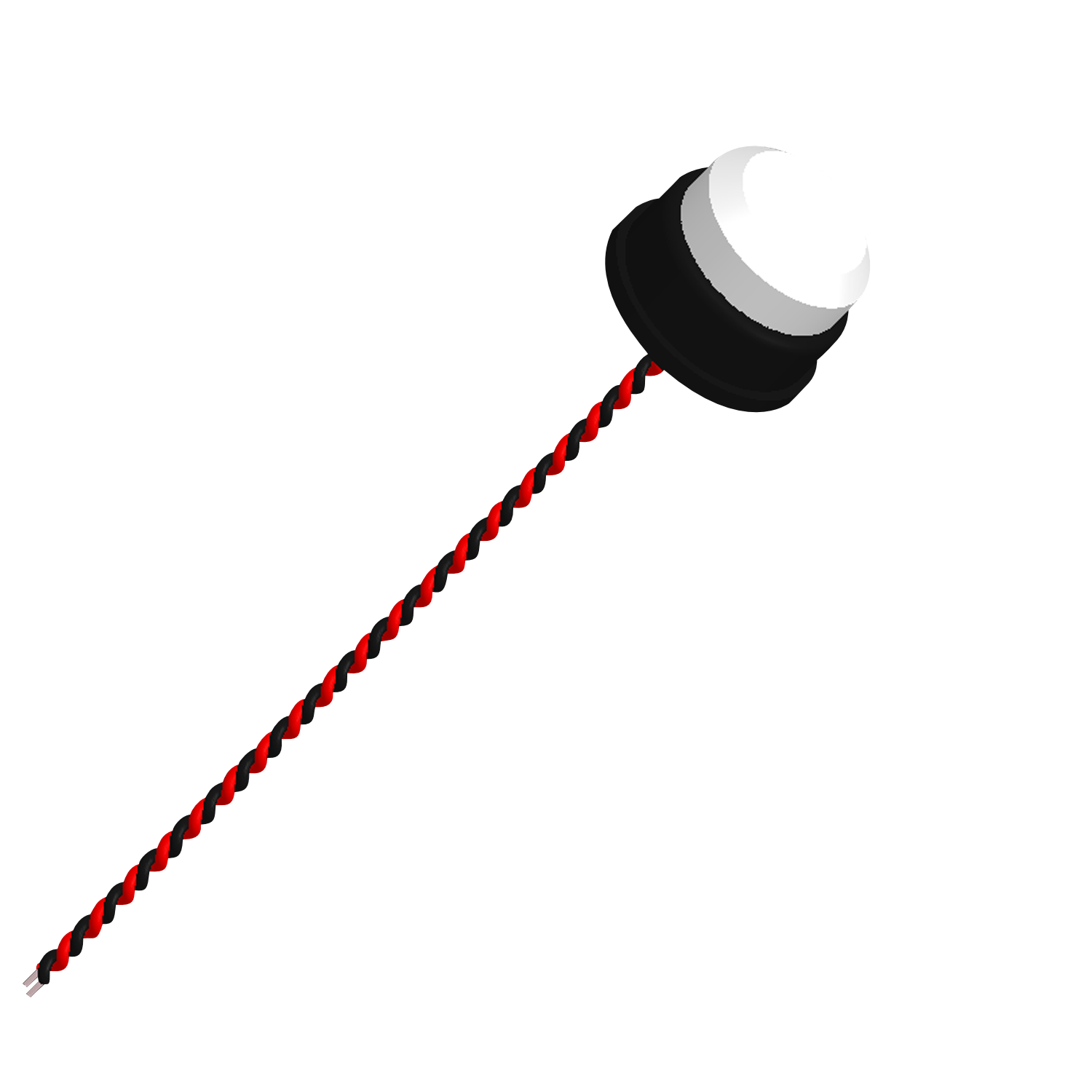

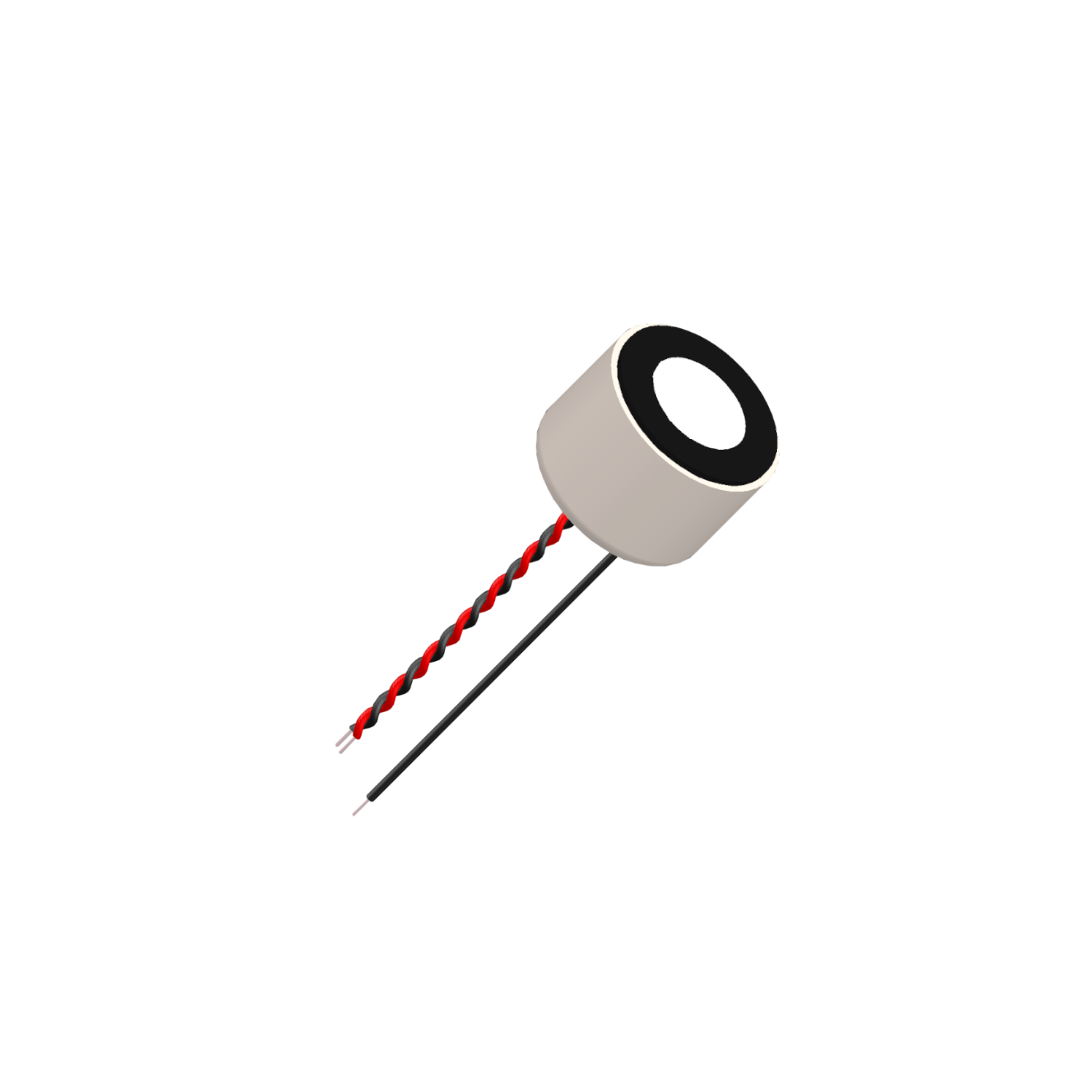

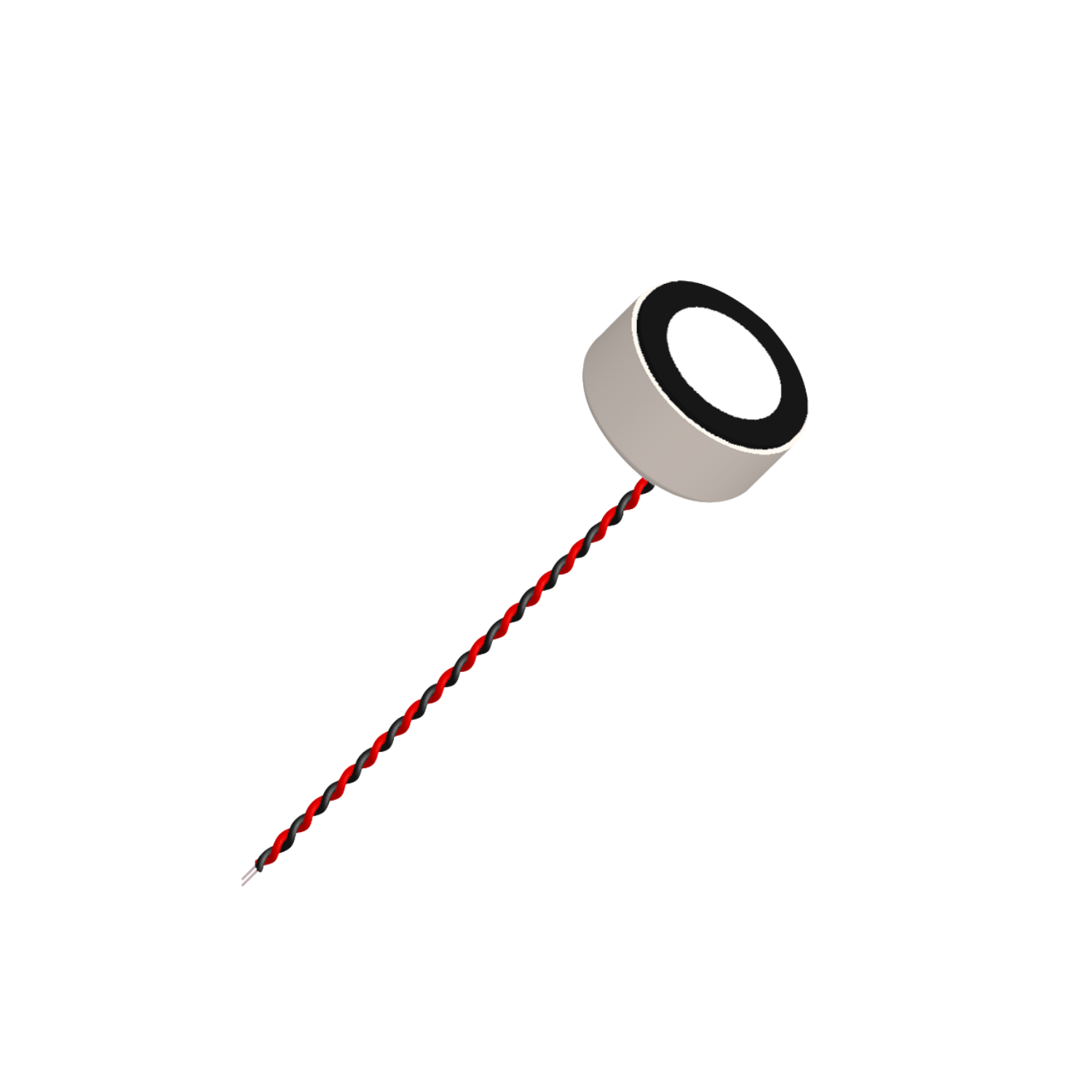

This method uses high-precision ultrasonic transducers that operate without contact and detect even the smallest differences in material thickness. The technology is based on measuring sound waves that are sent through the material. The thickness of the material is determined based on the transit time and reflection of the signals. This allows the system to detect double sheets in real time and ensure an immediate response in the production process.

The advantages of this solution are obvious: maximum precision, non-contact measurement, and flexible adaptation to different materials such as steel, aluminum, or coated sheet metal. Integration into automated production lines significantly increases process reliability, prevents downtime, and ensures that the quality of the end products remains consistently high. Especially in industries such as the automotive industry, sheet metal processing, and the textile and printing industries, double sheet detection using ultrasound is a decisive factor for efficiency and cost-effectiveness.